Our commitment is your assurance

To Whom It May Concern

Close quality control check is required to manufacture our products, strictly as per relative standards Our Vast 60 years experience in his field make us leaders.

In order to maintain this requirement, which is the heart of the complete manufacturing procedure, we have formed a regular practice to check the design, raw-material, semi finished product and finished product at every stage.

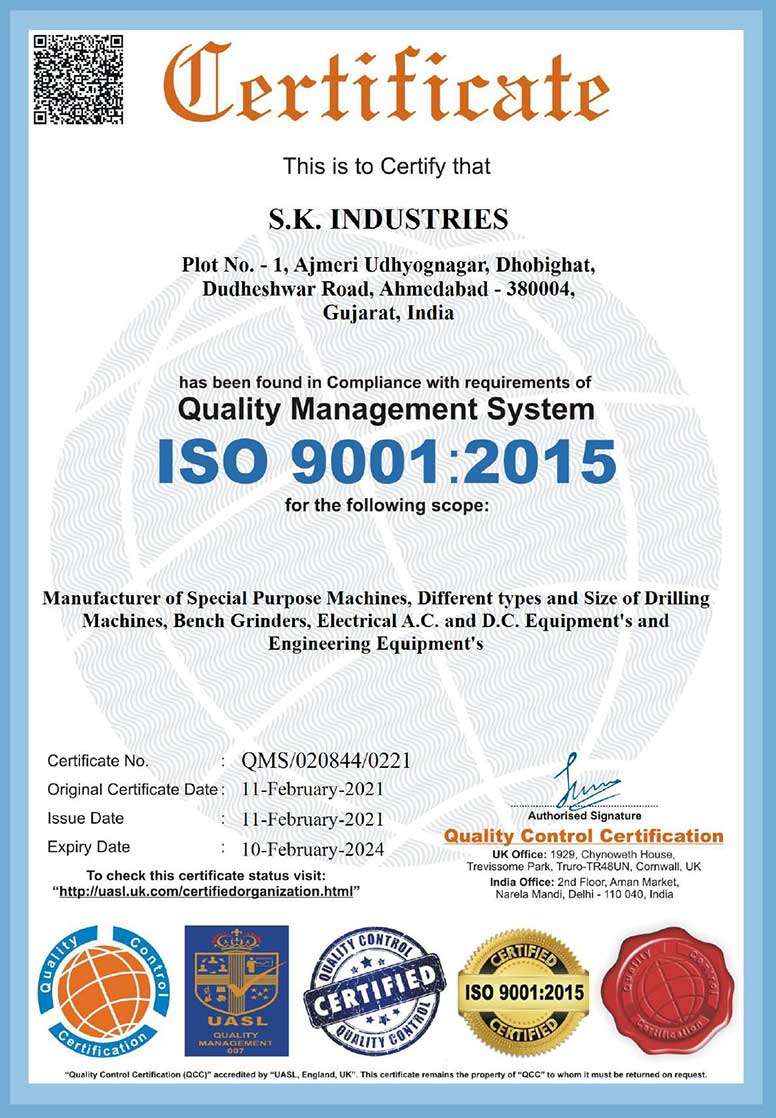

Quality Certificate

In short, our internal inspection follows a line of stage-wise inspection as briefed below.

- Company Have An ISO 9001:2008 Certificate.

- Executives & Engineers of this company are experienced in different fields of manufacturing activities like designing, production, planning & quality control.

Drawings of complete range of products are checked and approved by all Employees in all respect like specification of standards, specification of material and interchangeability of components, hence we can offer spares after supply.

Patterns of complete range of products are made strictly as per drawings and checked in all respects i.e contraction required for the respective material, machining margin required according to material & thickness and counter as per related standards

We are purchasing castings from well know foundry’s and using S.G.Iron material in Gears and Quill.

Main Shaft are made from 20mn CR5 materials and hardened 50-55 for better life and Its is threaded and taper bore is also Internal grinded in 20mm Capacity Drilling Machine.

We are using only SKF and FAG Bearings in our Machines.

Operator-friendly Head Cover for better Productions.

Main Gear and C.I. Pulley are perfectly Balanced to avoid vibration.

Columns are made our of seamless and Hard Crome Plated Steel tube to avoid rust for long time.

All the moveable part are machined in CNC Lathe machine.

Dimensional and visual inspection of all components during various machining stages and before assembly, Final finishing parting & painting under close supervision.

S.K. Industries Drilling machines is well known for its robust construction and suitable design, both for the production and Tool room. It executes operation is wide range of drilling, reaming, tapping, boring and counter boring in steel, casting and other materials.